This is a tool you might also find among the tools for dentists or dental technicians even in small sizes. So you don’t have to forge this tooltip necessarily on your own, if you can find it somewhere else. But if you want, this is how you can do it:

You can do this tool tip from 1,5, 2,0 or 3,0mm steel wire, but I think, the 3,0 wire would make a tool tip, that’s a little bit too big. For me, the 2mm v2a steel wire works best for that tip.

So first give your steel rod a long pointed tip. Make the tip, like I’ve explained for the long probe tool tip. But this time make the pointed tip shorter (about 5mm).

You can make the pointed tip like a cone (pic. 6a) or more like a bossed cone (like a cone that has been "blown up" with rounder edges, pic. 6b).

Then cut in a circular furrow under the tip. Don’t make this furrow too deep but just enough to form the cone-like tip. You’ll have to bend the steel later. If you make the furrow too deep, it will break. To get this furrow with an even depth is a bit tricky. For me the best way was to use two rotary tools (or one rotary tool and a power drill). The first rotary tool with a cutting wheel was fixed into a bench vice, while the other rotary tool holds the steel rod with the pointed tip. Then, while rotation both, the cutting wheel and the steel rod, touch slightly the edge of the cutting wheel with the rotating steel rod at the right point. Don’t press too much and try to avoid the steel rod starting to vibrate (pic. 7). The space between the tip and the furrow should be about 4-10mm, depending on the steel rods diameter.

In the next step you have to bevel the edge of the furrow that faces away from the tool tip. You can do this also by slightly touching the rotating cutting wheel with the rotating steel rod, but be sure, not to accidentally damage the already shaped tool tip (pic. 8).

After that clean up the surface of the tool tip and remove all scratches with abrasive paper and abrasive pads (keep the steel rod rotating in the rotary tool and drag it slowly over the abrasive paper).

At last you have to bend the tooltip, because then it’s easier to reach difficult areas on your sculpt. Do it like you can see on pic. 9.

Finally polish this tooltip and you’re done.

This tool is quite good especially while working on drapery and wrinkles.

THE DIAGONALLY CUT TOOL TIP (or "the eye tool")

This kind of tool tip I first saw on sculpting tools made by the German sculptor Stefan Niehues.

You can do this tool tip with every steel rod diameter you like and it always makes a nice addition to your tool set (even the 3mm version), because every size can be used for different sculpting needs.

With the smallest version, you can also form eyes, because with its special shape you can work out eyeball and eyelid quite well (if you got a calm hand of course). That’s why this tool tip is also called "eye tool".

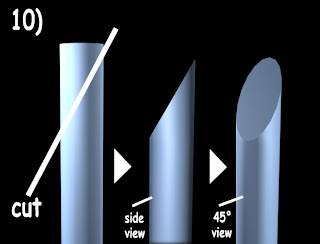

Basically the tool is just a steel rod that is diagonally cut, so it gets an angular (bevelled) tip. And that’s how you can do it. For a larger diameter tool tip, just make a diagonal cut into the steel rod with the cutting wheel and the rotary tool. If that doesn’t work well, you can also make a straight cut and grind it down with the cutting wheel, so it gets an angular shape (pic. 10).

For the smaller diameter tool tip, it might be a good idea, to take a larger diameter steel and to grind it down so it gets a long tip before shaping the angular tip from the narrowed rod (pic.11).

Then you have to clean the surface from the scratches as always.

But be sure to leave the edges at the narrowed tip "sharp".

So don’t use the abrasive pads here, because they will round the edges.

Just take fine abrasive paper, place it on a hard surface with the grind-side facing up and drag the narrowed face of the tool tip over it, so it gets perfectly flat (pic. 12).

Finally as always polish your tool tip but be sure not to round up the edges while polishing.

Stefan Niehues told me, that this tool tip is even better, if its narrowed face isn’t just 100% flat, but a little bit concave (dished). To achieve this, you would have to work with a ball-shaped grinding stone on a rotary tool and a very calm and firm hand. But if you like, just try this.

THE LONG SCULPTING KNIFE TOOL TIP

There’s one last tool tip that I want to explain for now. I call it the long sculpting knife and some sculptors told me, that they prefer to work with a tool tip like that.

Basically it looks like a knife blade. Maybe you’ve seen sculpting tools with similar tips among the tools for dental technicians. Even Games Worksop sells such a tool, but I didn’t like that so much because it’s quite rough and not shaped tidily (at least the one I bought some time ago).

To build a long sculpting knife tool tip, basically you have to start like I’ve explained for the straight spatula tool tip. But this time flatten the steel over a longer part of the steel rod. Remember, not to make the tip too flat (thin) because you also have to grind some material off for a good surface. After flattening the steel, just give it a knife-like pointed tip like you can see on pic. 13). Then "sharpen" the curved edge of the sculpting knife.

Keep a smooth rounded surface while doing that, so that there are no edges on the flat sides of the "blade". Remember: "Sharp" doesn’t mean razor-like here. Just give it a thin edge. You could leave the straight edge of the sculpting knife (the backside of the "blade") blunt or you can also sharpen it. After that remove the scratches from the surface and do some polishing and you’ve got another tool tip.

So I think, for now, there are enough tool tips for you to build, and I think it might be good to stop here for now. I guess, from time to time I will present some more tool tips in my blog. If you have made a special tool tip, that you want to share with the community, just send me an email.

Next time I will tell you about polishing the tool tips and then I will explain how to build handles for the tool tips.

It's rather awesome,I have been searching relate to these stuffs for me .And it really helps me.Article that appeared good enough to be read so that adds to knowledge when reading

ReplyDeleteThanks forr this

ReplyDelete